Digitalisation

At Layher, we understand the consequences and costs that can be associated with poorly executed designs and lack of pre-planning. Which is why we make smarter value optimisation choices with you for your specific needs, long before you erect scaffolding.

Using state-of-the-art, cutting-edge technology built on over 80 years of global knowledge and expertise, Layher offers its partners a unique competitive advantage in the marketplace that sets them up for success well before the build and ensures that everything is thought out ahead of time, so there are no surprises.

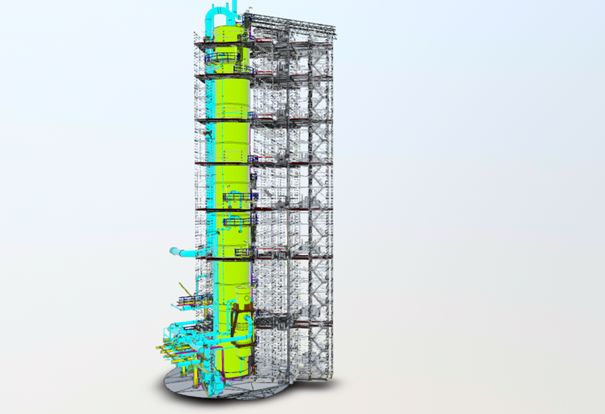

Layher’s pre-planning and optimisations are essential in the project’s initial planning phase, which allows you to look ahead of time in a 3D virtual reality that we build for you to see our scaffold systems and how they are the right solution for your project needs. Our recommendations are based on how to best optimise the project, from designing the best scaffold system for time efficiencies to foreseeing potential issues that could occur and reducing those risks, to logistical planning of product delivery. This also helps us ensure that you do not procure items that you do not necessarily need and also optimally utilise everything you invest in.

How do we do it?

Layher experts perform a walk-through to identify site specifications affecting shutdown and find ways to prevent delays and optimise logistics.

We go to the jobsite of the plant and do an initial evaluation, which may also include 3D scanning if required

Together with our scaffold partners, we create a conceptual design using our LayPLAN suite.

Based on a 3D scan or plant drawings, we develop a detailed scaffold that is optimised for your project

We let the customer into the scaffold virtually using Virtual Reality and guide them on what they need and don’t need for their project

We plan it out for different trades and scenarios so there are no surprises on the project, and show you how the scaffold would look on the ground virtually using our SIM2Field

We streamline and cut down shutdown costs or downtime because everything’s thought out ahead of time.